花生脱壳机如何进行日常维护?

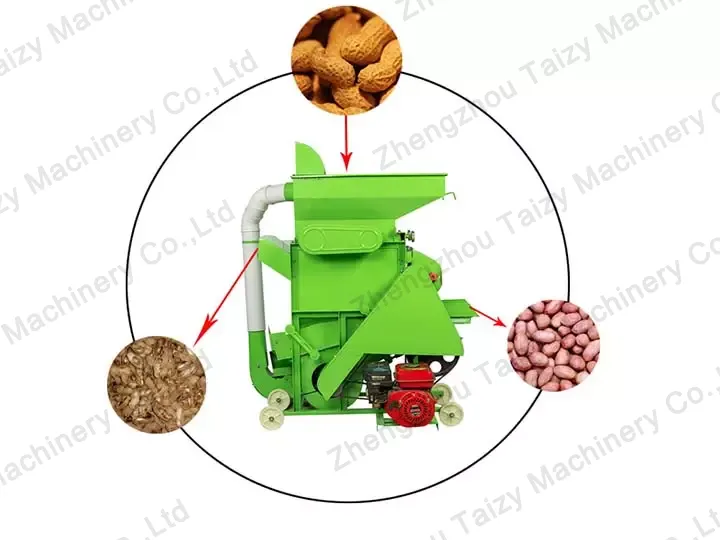

花生脱壳机在农业领域发挥着至关重要的作用,通过有效去除花生壳,大大提高加工效率。为了保持花生剥壳机平稳运行并保持最佳生产水平,定期维护以获得最佳机器性能至关重要。

日常清洁的重要性

每天操作后,请务必彻底清洁机器,以清除任何剩余的花生、贝壳碎片或碎片。定期和全面的清洁不仅可以保持机器的清洁,还有助于防止可能导致堵塞或损坏内部组件的材料堆积。

为避免腐蚀或损坏精密部件,请使用专为农业机械配制的专业清洁剂。这保证了深度清洁,同时保持了机器的完整性。

操作前检查

对易磨损的部件保持警惕,包括叶片、轴承和密封件。任何损坏或异常磨损的迹象都必须立即处理,以避免中断和昂贵的维修。

如果您发现任何零件磨损或损坏,请迅速采取行动更换或修理它们。手头备有备件可以减少停机时间并保证您的花生剥壳机顺利运行。

定期润滑

每次使用后,请在轴承、齿轮和其他重要部件上涂抹高质量的润滑剂,以保持它们平稳高效地运行。

确保使用制造商推荐的特定类型的润滑剂,并避免混合不同的油,因为这可能会导致过早磨损并导致设备故障。

检查螺栓是否松动

随着时间的推移,操作振动会导致螺栓和螺钉松动。在每个工作日结束时检查并拧紧所有连接非常重要,以避免零件松动,从而导致故障或损坏。

确保所有部件都牢固紧固不仅可以保持机器的完整性,还有助于防止事故并提高整体安全性。

定期保养

除了日常工作之外,还应制定满足花生脱壳机特定要求的定期维护计划。这可能涉及磨刀片、更换密封件和进行内部清洁等活动。

尽管定期维护至关重要,但过度维护可能会产生损害。遵守制造商的指南,以防止可能缩短机器使用寿命的不必要的维修或更换。

结论

对于旨在增强或投资一流的农民和加工商 花生 对于剥壳机来说,选择一台具有可靠维护协议且易于获取备件的机器至关重要。 (阅读更多: 花生脱壳机|花生脱壳机>>) 我们提供全面的支持和培训,我们邀请您与我们合作,以确保您的花生加工业务取得成功。