Kichimbaji cha Mafuta ya Karanga | Mtoa Mafuta ya Karanga

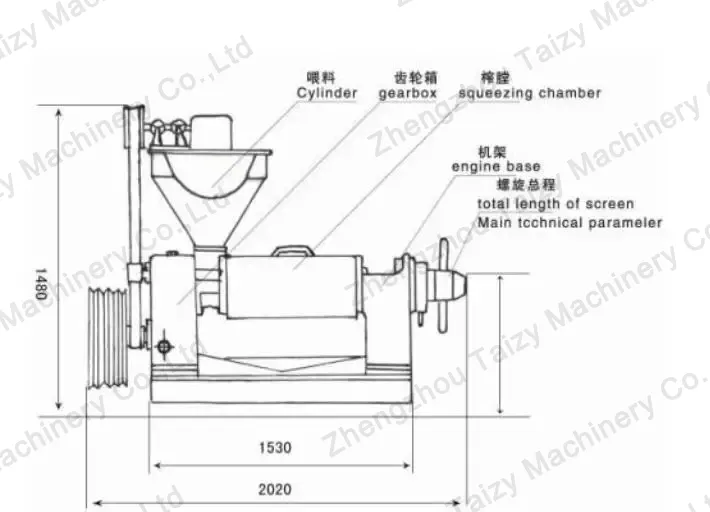

| Mfano | TZ-180 |

| Bonyeza Kasi | 37r/dak |

| Uwezo | 150-230kg / h |

| Uzito | 1100kg |

| Ukubwa | 1.9*1.2*1.3m |

| Bonyeza Kipenyo | 100 mm |

| Pumpu ya Utupu | 0.75kw |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Kichunaji cha mafuta ya karanga kiotomatiki ni mashine iliyoshikana iliyoundwa kwa ajili ya kuchimba mafuta ya kula kutoka zaidi ya aina ishirini za mbegu za mafuta, zikiwemo karanga, soya, alizeti, rapa na zaidi. Kimsingi hutumika katika kaya binafsi na shughuli ndogo za kusukuma mafuta.

Mashine hii inaweza kufikia ufanisi wa uchimbaji wa mafuta wa 20%- 50% ya uzito wa mbegu, kuongeza mavuno ya mafuta kwa 35%- 50% ikilinganishwa na mashinikizo ya kawaida ya mafuta, na kuokoa 60% ya nishati kwa pato sawa.

Aina ya matumizi ya mashine ya kuchapa mafuta

Chombo hiki cha mafuta ya screw kimeundwa kwa ajili ya usindikaji wa aina mbalimbali za mafuta ya mboga na karanga. Mifano ni pamoja na mbegu ya haradali, alizeti, rapa, soya, castor, shea nut, nazi au copra, mbegu ya mwarobaini, pamba, jatropha, mbegu ya mahindi, flaxseed, palm kernel, karanga, ufuta na zaidi.

Iwapo huna uhakika kama malighafi yako yanafaa kwa kichimbaji chetu cha mafuta ya karanga, usisite kuwasiliana nasi. Tunatoa majaribio ya bure ya malighafi yako.

Jinsi ya kuchimba mafuta kutoka kwa mbegu za karanga?

Kichunaji cha mafuta ya karanga skrubu kimsingi huundwa na vipengele vitano muhimu: kisanduku cha kudhibiti kiotomatiki, sehemu ya kupasha joto na kubofya, utaratibu wa kurekebisha, sehemu inayozunguka, na mfumo wa kuchuja mafuta ya utupu. Kati ya hizi, sehemu ya kupokanzwa na kushinikiza ni muhimu zaidi kwa operesheni nzima ya mashine.

Maandalizi ya mbegu za mafuta kabla ya usindikaji au uchimbaji yanaweza kutofautiana kwa kiasi fulani, lakini inategemea maudhui ya mafuta na sifa za kimwili za mbegu za mafuta. Hata hivyo, karibu mbegu zote za mafuta hupitia taratibu za kawaida za kusafisha mbegu, kukausha, kupunguza ukubwa, kupiga flaking, kupika, na hali ya mwisho.

- Anza kwa kumwaga kokwa za karanga kwenye hopa. Utaratibu wa skrubu ya mashine kisha utasukuma nyenzo mbele. Wakati nafasi kati ya chumba cha waandishi wa habari na screw ya kushinikiza inavyopungua, wiani wa nyenzo za mafuta huongezeka.

- Kwa hivyo, shinikizo la ndani pia huongezeka. Utaratibu huu hutoa joto kwa sababu ya msuguano kati ya nyenzo za mafuta na sehemu za mashine wakati wa kushinikiza. Shinikizo huvunja muundo wa seli za karanga, kuruhusu mafuta ya karanga kutolewa.

- Kisha, mafuta ya karanga hupitia sehemu ya kuchuja utupu, ambapo mabaki yoyote ya mafuta hutenganishwa na kukusanywa juu ya kitambaa cha chujio. Mwishowe, tunapata mafuta safi ya karanga. Hii inaelezea mchakato kamili wa kuchimba mafuta ya karanga.

Screw karanga mafuta extractor faida

- Alama ndogo. Inahitaji mita za mraba 10-20 tu za nafasi.

- Chumba cha kushinikiza kilichoundwa vizuri huongeza shinikizo la ndani, kwa kiasi kikubwa kuongeza ufanisi wa kazi.

- Mbalimbali ya maombi. Mashine hii inaweza kusindika zaidi ya aina 20 tofauti za malighafi kwa uchimbaji wa mafuta.

- Ufanisi wa juu. Mtoa mafuta yetu ya karanga anaweza kushughulikia kilo 500 za malighafi kila saa, na inaweza kuendeshwa na mtu mmoja tu.

- Imeundwa kutoka kwa chuma cha kaboni cha ubora wa juu, ni thabiti, hudumu, sugu na imeundwa kwa ajili ya mgandamizo wa mafuta unaoendelea.

- Kiwango cha juu cha pato la mafuta. Kichunaji cha mafuta ya karanga kinaweza kupata mavuno ya takriban 50%, na mabaki ya keki kavu kuwa 8% au chini.

Vigezo vya mashine ya kuchimba mafuta ya karanga

| Mfano | TZ-60 | TZ-70 | TZ-80 | TZ-180 | TZ-125 |

| Bonyeza Kipenyo | 55 mm | 65 mm | 80 mm | 100 mm | 125 mm |

| Bonyeza Kasi | 64r/dak | 38r/dak | 35r/dak | 37r/dak | 34r/dak |

| Injini | 202kw | 3 kw | 4kw | 7.5kw | 15kw |

| Pumpu ya Utupu | 0.75kw | 0.75kw | 0.55kw | 0.75kw | 0.75kw |

| Nguvu ya Kupokanzwa | 0.5kw | 1.1kw | 2.2kw | 3 kw | 3.75kw |

| Uwezo | 40-60kg / h | 50-70kg / h | 80-120kg / h | 150-230kg / h | 300-350kg / h |

| Uzito | 240kg | 280kg | 850kg | 1100kg | 1400kg |

| Ukubwa | 1.2*0.48*1.1m | 1.4*0.5*1.2m | 1.7*0.11*1.6m | 1.9*1.2*1.3m | 2.6*1.3*2.3m |

Ni karanga gani iliyo bora zaidi kwa uchimbaji wa mafuta?

- Fikiria ukubwa wa punje ya karanga. Ikiwa punje ya karanga ni kubwa sana, haitatoshea kupitia ufunguzi wa malisho wa mashine ndogo za kukandamiza mafuta. Kinyume chake, ikiwa punje ni ndogo sana, kasi ya chini ya mto itakuwa kubwa sana, ambayo inaweza kuzuia mavuno ya mafuta. .

- Angalia ikiwa punje ya karanga ni mbichi. Ni muhimu kwamba karanga zinazotumiwa kwa uchimbaji wa mafuta zisiwe na ukungu, kwani kokwa zenye ukungu zina aflatoksini, kasinojeni yenye nguvu.

- Chunguza aina mbalimbali za kokwa za karanga. Kuna aina kadhaa za karanga, ikiwa ni pamoja na karanga za kawaida, karanga za lulu, karanga za nafaka nyingi, na karanga za joka. Aina ya kawaida ndiyo inayofaa zaidi kwa uchimbaji wa mafuta, ikijivunia maudhui ya mafuta ya 52-54%.

Jinsi ya kuanza biashara ya uchimbaji mafuta ya karanga?

- Fanya uchambuzi wa kina wa soko. Ni muhimu kuamua kama karanga zinalimwa katika eneo hilo, kutathmini ubora wa karanga, kuelewa mahitaji ya ndani ya mafuta ya karanga, na kutathmini viwango vya mapato ya wakazi.

- Chagua eneo linalofaa ili kuanzisha biashara ya uchimbaji wa mafuta ya karanga. Baada ya hapo, pata leseni muhimu ya biashara kutoka kwa idara husika ya serikali.

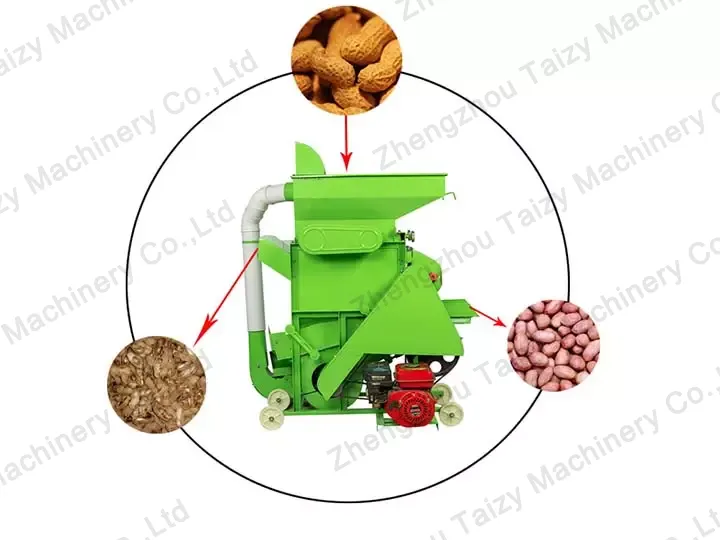

- Nunua vifaa vya mashine ya kusindika mafuta ya karanga. Ikiwa unataka kuanza kiwanda cha mafuta ya karanga, basi mafuta ya karanga haitoshi. Unahitaji mashine ya kukoboa karanga, mashine ya kumenya karanga, uchimbaji wa mafuta ya karanga, mashine ya kujaza karanga, na vifaa vingine vinavyohusiana

- Soko mafuta yako ya karanga. Hatimaye, unahitaji kutafuta njia za mauzo ili kuuza mafuta yako ya karanga.

Tunakaribisha maswali katika Kiingereza, Kifaransa, Kiarabu, Kihispania, Kirusi, na lugha nyingine nyingi. Timu yetu ya wataalamu itakujibu ndani ya siku moja ya kazi. Usisite kuwasiliana nasi!