Peanut Peeling Machine | Groundnut Skin Remover

| Model | TZ-1 |

| Capacity | 200-300kg/h |

| Motor Power | 0.55kw |

| Fan Power | 0.37kw |

| Voltage | 380V/220V |

| Frequency | 50HZ |

| Peeling Rate | ≥98% |

| Size | 1100*400*1100MM |

You can now ask our project managers for technical details

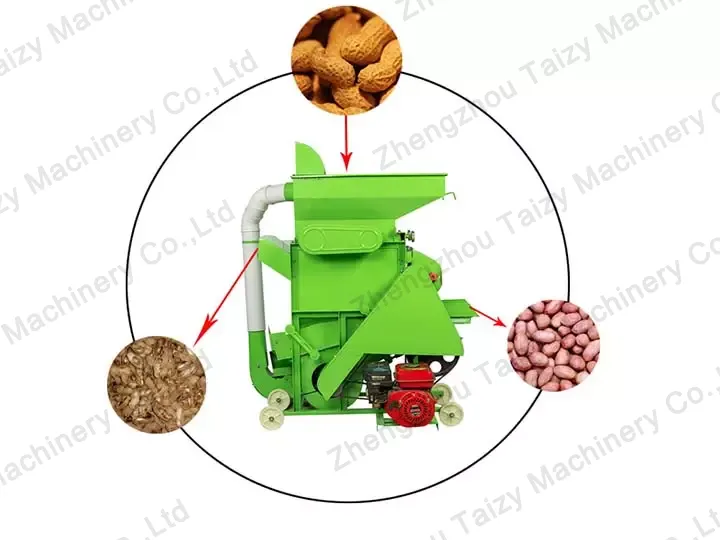

The peanut peeling machine is specifically designed to remove the red skin from peanuts. It utilizes a differential rolling friction transmission system, which helps keep the peanut kernel intact and enhances the flavor of the peanuts. It is also suitable for processing almond kernels, soybeans, fava beans, and more.

Our factory offers a variety of models for the peanut red skin shelling machine, with output capacities ranging from 200 to 1000 kg/h. The shelling rate can reach 98% or higher, while the kernel breakage rate remains below 2%.

Why peanuts peeling being so popular?

This peanut peeling machine is commonly utilized in the production of various peanut products, including fried peanuts, multi-flavored peanuts, peanut milk, peanut protein powder, peanut candy, peanut brittle, peanut cake, peanut butter, canned foods, and more.

Peeled peanut kernels are among the most popular exotic peanut products. We offer machines in versatile designs with a broad selection of models to choose from. For local businesses processing peanut products, investing in a peanut peeling machine is a significant commitment that can yield substantial profits.

Requirements for peanut raw materials

- The moisture content of the ingredients after frying or roasting is approximately 4%.

- It’s important to control the temperature; if it gets too high, it can negatively impact the peeling process and potentially harm the machine.

- The raw materials that require peeling should be free of impurities like iron filings and stones to avoid damaging the equipment.

Typically, peanuts need to be processed in a peanut roaster before they can be peeled. For more details, check out Roasted Peanuts Machine | Groundnut Roaster.

Dry type groundnut peeler advantages

- The machine is compact, making it simple to install and operate.

- The machine is made of stainless steel, clean and hygienic, sturdy and durable.

- It uses a dry method, which means there is no water consumption and no environmental pollution.

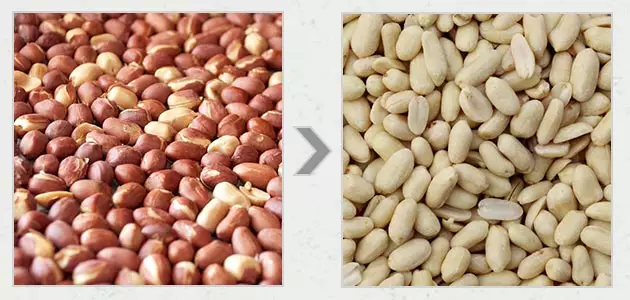

- The processed peanut kernels have a low crushing rate and an excellent appearance.

- The blower collects the red skins, allowing for easy use in other applications like pharmaceuticals.

Machine design and working principle

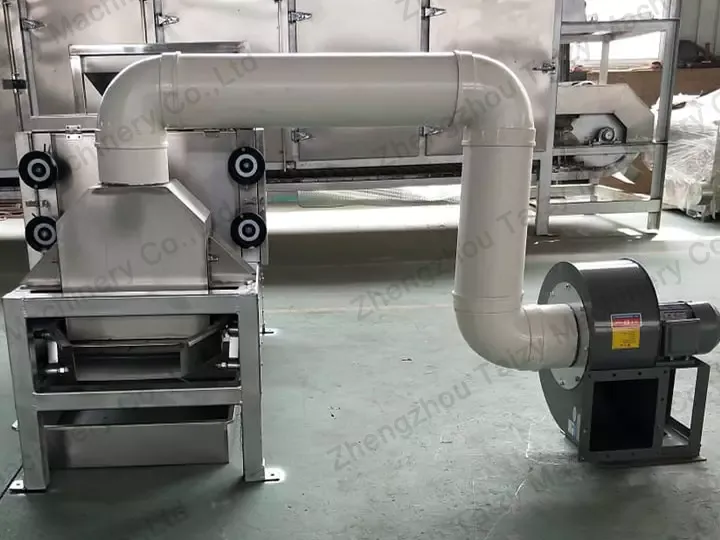

This dry type peanut peeling machine includes a feeding hopper, three drums, a dual-layer vibrating screen conveyor, a centrifugal fan, and an outlet.

It features a roller-rubbing structure where dried peanut kernels are fed into the main machine from the hopper. The red outer skin is removed by the high-speed rotating rubbing roller, and the peeled peanut kernels are discharged from the front feed opening. Meanwhile, the peanut skins are blown out by the fan from the opposite side and collected.

Peanut peeling machine parameters

| Model | Capacity | Motor Power | Fan Power | Voltage | Frequency | Peeling Rate | Size |

| TZ-1 | 200-300kg/h | 0.55kw | 0.37kw | 380V/220V | 50HZ | ≥98% | 1100*400*1100MM |

| TZ-2 | 400-500kg/h | 0.55kw*2 | 0.37kw | 380V/220V | 50HZ | ≥98% | 1100*700*1100MM |

| TZ-3 | 600-800kg/h | 0.55kw*3 | 0.37kw | 380V/220V | 50HZ | ≥98% | 1100*1000*1100MM |

| TZ-4 | 800-1000kg/h | 0.55kw*4 | 0.37kw | 380V/220V | 50HZ | ≥98% | 1100*1400*1100MM |

Wet type groundnut skin remover machine

The wet peanut peeling machine is designed for unroasted peanuts. After this machine peanut peeling has the characteristics of a high integrity rate. You can get more information about this machine by reading Wet Groundnut Peeling Machine.

Unlike the dry-type peanut red skin peeling machine, this one utilizes rubber roller friction to effectively peel peanuts. To start, it’s important to soak the peanut beans in advance. Next, pour the soaked peanuts into the hopper. As the rubber rollers create friction, the red skin will be separated from the peanut beans. In the end, the peeled peanuts will exit through the discharge port, while the red skin is expelled from a different outlet.

Machine parameters

| Model | ZYC-100 | ZYC-180 |

| Power | 0.75kw(380v),1.1kw(220v) | 0.75kw(380v),1.1kw(220v) |

| Peeling Rate | 92%-95% | 92%-95% |

| Capacity | 100-150kg/h | 200-250kg/h |

| Size | 1180*720*1100mm | 1180*850*1100mm |

How to maintain the machine?

- Make sure to clean the sanding rollers regularly.

- If the single sand isn’t rotating, it’s time to replace the belt.

- Regularly clean the fan impeller, as it can accumulate peanut powder and shredded skins.

- After finishing work, use a brush to clear any residue from the sanding rollers and to clean out the storage bag (or box) that holds the shredded skin fragments.

- Be sure to empty the peanuts and pellets from the fan bucket every day, and open the sliding door at the bottom of the machine to release the pellets.

Cost of groundnut peeling machine

As a leading manufacturer of peanut peeling machines, we offer a variety of models to suit your needs. Each type of peeling machine comes with its price point. Additionally, factors such as distance, output capacity, and tax rates can influence the overall cost of the peanut processing machine. This means that prices can vary significantly.

The machine is user-friendly, ensures a hygienic process, and is efficient in saving both labor and electricity. Additionally, it plays a crucial role in the peanut butter production line and coated peanut production line.

If you’re interested in receiving a detailed quote for a machine, please reach out to us with your specific requirements, and our sales team will provide you with a clear quotation.