Peanut Butter Filling Machine | Food Paste Packaging Machine

| Name | 4 Heads Filling Machine |

| Material | Stainless Steel |

| Driven Type | Pneumatic & Electric |

| Filling Volume | 500-3000ml |

| Filling Speed | 480KG-1920KG |

| Hopper Volume | 350L |

| Power | 220V, 50Hz, 500W |

| After-Sales Service | Warranty: 1 year; Video Technical Support |

You can now ask our project managers for technical details

The peanut butter filling machine is specially designed for liquid and viscous sauces, which are widely used in the automatic packaging of peanut butter, sesame seed paste, jam, and other food products.

This equipment is a key link in the peanut butter production line, which not only improves the filling efficiency but also guarantees the cleanliness and stability of the packaging process.

Whether it is a small workshop just starting or a factory with batch production, we can provide both fully automatic and semi-automatic models to meet the actual needs of different customers.

Peanut butter packing machine application scope

- Sticky foods such as peanut butter, sesame butter, hot sauce, jam, etc.

- Fluid condiments such as honey, condensed milk, salad dressings, ketchup, etc.

- Cosmetics such as lotions, creams and other semi-fluid products.

- Creams and liquid medicines in the pharmaceutical industry.

- Chemical industry oils, lubricants, detergents, etc.

Advantages of peanut butter filling machine

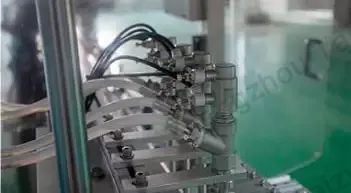

- Anti-drip design: the filling nozzle is equipped with anti-drip device, which is automatically closed at the end of filling to avoid product waste and pollution.

- Safe operation: equipped with liquid tray to collect residual liquid, keep the equipment neat and clean, reduce the residue on the ground, and ensure the sanitation of the production environment.

- Convenient cleaning: reasonable structural design, simple disassembly, easy to clean and maintain, in line with food hygiene standards.

- Strong bottle compatibility: adjustable structure is suitable for different sizes of bottles, no need to replace parts, saving conversion time.

- High degree of automation: fully automatic or semi-automatic system according to customer requirements, greatly improving production efficiency and reducing labor costs.

Peanut butter filler machine working principle

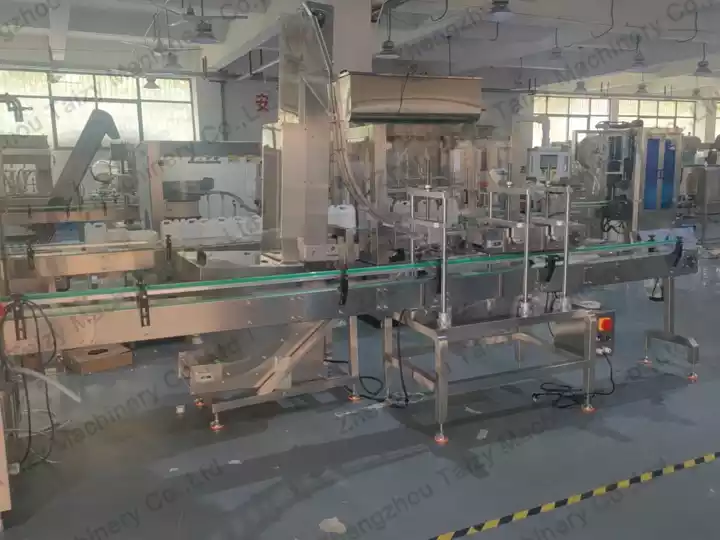

Peanut butter filler consists of an independent filling nozzle, electronic touch screen, conveyor, and electric control cabinet.

- Starting the equipment: after the power is turned on, the machine starts to run and the pneumatic piston pump is activated, ready to perform the suction and filling action.

- Suction process: the pneumatically controlled piston pump draws peanut butter and other materials from the storage tank into the quantitative metering cylinder.

- Automatic positioning: when the dosing cylinder sucks in the set amount of peanut butter, the filling nozzle automatically moves to the top of the bottle mouth for positioning.

- Filling and discharging: the valve of filling nozzle drops, peanut butter is quantitatively injected into the packaging bottle through the material pipeline.

- Precise control: users can adjust the stroke or parameters of the pneumatic piston pump to precisely control the filling quantity each time.

- Anti-drip function: after the filling is finished, the nozzle closes automatically to prevent dripping and ensure clean and sanitary filling.

Nut butter filling machine parameters

| Name | 4 Heads Filling Machine |

| Material | Stainless Steel |

| Filling Head | 4 Heads |

| Driven Type | Pneumatic & Electric |

| After-Sales Service Provided | Warranty: 1 year; Video Technical Support |

| Filling Volume | 500-3000ml |

| Filling Speed | 2 Heads: 240KG-960KG; 4 Heads: 480KG-1920KG |

| Hopper Volume | 350L |

| Power | 220V, 50Hz, 500W |

| Machine Size | 1850mm*1040mm*1900mm |

| Weight | 700KG |

Do you want to get the complete peanut butter filling system?

If you not only need a peanut butter filling machine, but also want to set up a complete and efficient filling production line, Taizy can provide you with a professional complete peanut butter filling system.

The entire line covers the entire process from coding and labeling to filling and capping. The equipment includes coding machine, labeling machine, filling machine and capping machine, each step of the production line is accurate, efficient and automated to ensure the products are neat, beautiful and standardized.

Whether for supermarkets, wholesale markets or e-commerce platforms, peanut butter products filled with this system can achieve uniform and standardized packaging results, helping you create a professional brand image.

We can provide flexible configurations according to your output demand and budget, welcome to consult for detailed solutions and quotations at any time.

Customized peanut butter filling machine for sale

Taizy peanut butter filling machine is not only easy to operate and compact, but also has practical features such as anti-drip design, easy to clean, and adaptable to a variety of bottle types.

We produce both peanut butter production line equipment suitable for large-scale production, as well as small peanut butter processing machinery suitable for small and medium-sized enterprises or start-up factories, with high cost performance and a low investment threshold.

In addition, the equipment has a wide range of applications, not only for filling peanut butter, but also for filling production of liquid or viscous materials such as ketchup, jam, honey, juice, skin cream, shampoo, and so on. It is widely used in many industries such as food, condiments, daily chemicals, pharmaceuticals, and so on.

Whether you want to expand production capacity, improve efficiency, or plan to start from scratch in the peanut butter processing industry, we can provide you with one-stop solutions and attentive after-sales service. Feel free to contact us for customized solutions and quotes to make your filling production more efficient, professional and reliable!