ラッカセイの殻むき業者 |ピーナッツ殻むき機

| モデル | TBH-800 |

| 全体の寸法 | 1330*750*1570mm |

| 生産性 | 600-800kg/h |

| 破損率 | ≤2.0% |

| 砲撃速度 | ≥98% |

| 力 | 3kw、220v、50hz、銅モーター |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

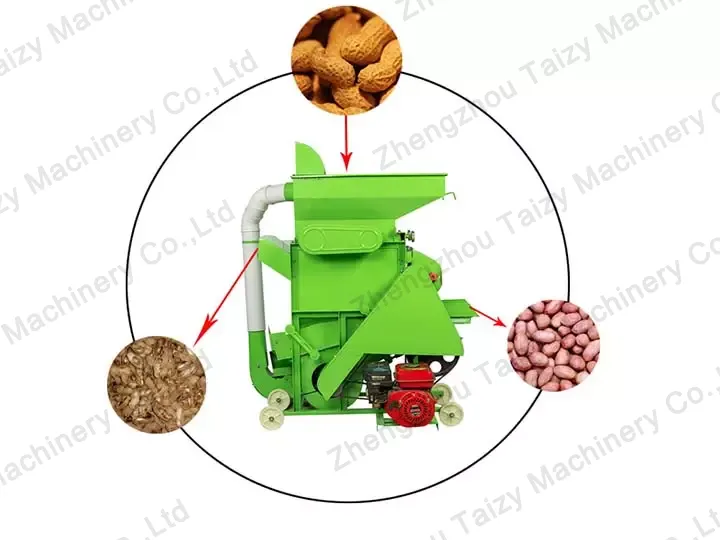

落花生殻むき機は、ピーナッツから硬い殻を効率的に取り除き、赤い皮のピーナッツ粒を得るように設計されています。さまざまなサイズと種類の落花生に対応し、98%以上の脱殻率と2%未満の低い破砕率を実現します。コンパクトで車輪付きのモデルも多く、さまざまな作業現場への移動が容易です。

殻をむいたピーナツの kernnels はピーナツバター、ピーナツオイル、およびピーナツキャンディの生産に利用できます。その結果、ピーナツの殻むき機は ピーナツバター生産プラント、油の抽出プラント、および食品加工作業で価値があります。

ラッカセイの殻むき機の動作原理

- ピーナッツは手動で供給ホッパーに供給され、その後ローラーまで転がされ、そこで二重ローラーからの繰り返しの摩擦と圧力によってピーナッツの殻が穀粒から分離されます。

- 殻をむくプロセスの後、ピーナツの殻と粒の両方がグリッドから落ちます。エアダクト内では、ピーナッツの殻の大部分が機械から吹き飛ばされ、ピーナッツの粒と砕けた殻の一部は重力分離スクリーン上に移動し、振動スクリーンの両側に移動します。

- 落花生の粒は排出口から出て、砕かれた殻は反対側のプレートファンによって吹き飛ばされます。同時に、殻を剥かれたピーナッツは第 2 搬送装置に導かれ、搬送ホッパーを介して供給開口部に輸送され、第 2 の殻をむきます。

自動ピーナッツ殻むき機の設計

各種ラッカセイ機はシンプルでコンパクトな構造をしています。それらの原理は一般に類似しており、手動給餌、ダブルドラムの 2 回目の脱穀、風による一次選別、重力選別ふるいによる選別、ピーナッツ果実の 2 回目の脱穀、およびファンや重力選別ふるいなどのコンポーネントが含まれます。

ピーナッツの殻むきのパラメータ

TBH-200、TBH-400、TBH-800などの落花生殻むき機を各種取り揃えております。小型のピーナッツ殻むき機の出力は 200 kg/h ですが、大型モデルは 5000 ~ 8000 kg/h の出力を達成できます。以下に 2 つのモデルのパラメータ情報を示します。

| モデル | TBH-800 |

| 全体寸法(mm) | 1330*750*1570 |

| 正味重量 (kg) | 160 |

| 生産性(kg/h) | 600-800 |

| 破損率 | ≤2.0% |

| ダメージ率 | ≤3.0% |

| 砲撃速度 | ≥98% |

| 力 | 3kw、220v、50hz、銅モーター |

| 関数 | 落花生の殻むき・殻むき |

| モデル | TZ-5000 |

| 全体寸法(mm) | 2750*1800*3360 |

| 正味重量 (kg) | 2850 |

| 生産性(kg/h) | 5000-8000 |

| 破損率 | ≤5.0% |

| ダメージ率 | ≤0.5% |

| 砲撃速度 | ≥99% |

| 電力(kw) | 42.5 |

| 動作湿度 | 6.3≦12 |

家庭用には小型のモデルを選択することもできますが、どちらのモデルも仕事中は優れたパフォーマンスを発揮します。この他にも、他のモデルの機械もございます。ご入用の際はお気軽にお問い合わせください。

Taizy 落花生殻むき機の利点

- この機械は高品質の鋼で作られており、頑丈で耐久性があり、長寿命を誇ります。

- 98%以上を達成する高い砲弾レートが特徴です。これにより、同様のマシンに対して大きな優位性が得られます。

- 高い洗浄率は、ピーナッツの殻を粒から効果的に分離する独自のファン設計によるもので、その結果、ピーナッツの粒がよりきれいになります。

- この落花生殻むき機は汎用性が高く、ピーナッツバター生産施設、搾油機、食品加工工場などで広く利用されています。

- お客様の要件に応じて、機械に電動モーター、ガソリンエンジン、またはディーゼルエンジンを装備できます。

落花生の水分に注意

ピーナッツの水分レベルは適切である必要があります。乾燥しすぎると破砕率が高くなり、湿りすぎると作業効率に影響します。適切な水分含有量を達成するには、次の方法を使用できます。

- 冬は殻をむく前に、落花生50kgに対して約10kgの温水を均等に噴霧し、ラップで覆って10時間ほど置きます。その後、1時間ほど日光に当てて殻むきの準備をします。他の季節では、残りの手順は同じで、カバー時間は約 6 時間となります。

- もう一つの方法は、乾燥した落花生をプールに浸し、すぐに取り出し、ビニールフィルムで約 1 日覆い、その後天日で乾燥させることです。水分含有量が適切になったら、殻をむくことができます。

天日乾燥させた生落花生の殻をむくには落花生殻むき機が使用され、効率が高く、操作が簡単、分割率が低く、メンテナンスコストが低いなどの利点があります。

ピーナッツの殻を取り除く機械はどこで購入できますか?

プロフェッショナルな落花生殻むき機のメーカーとして、私たちはピーナツの殻むき機だけでなく、関連機器のラインを提供します。ピーナツバター生産ライン、ピーナツ peeling 機、ピーナツバター機、ピーナツブリットル機など。

落花生皮むき機の信頼できるサプライヤーをお探しの場合は、お客様の特定のニーズを満たすカスタマイズされたサービスを提供できます。また、殻むきと洗浄の両方の機能を備えた複合ピーナッツ殻むきユニットも提供しています(下のビデオを参照)。

現在まで、私たちの落花生殻むき機はナイジェリア、トルコ、ザンビア、ベルギー、アフガニスタン、セントクリストファー・ネイビス、ギリシャなどの国々に輸出されています。機械にご興味がある方は、どうぞお気軽にお問い合わせください。

よくある質問

この落花生の脱穀機の処理能力はどのくらいですか?

当社の落花生脱殻機の処理能力はモデルによって異なり、通常は1時間あたり500kgから2000kgの範囲で、さまざまな生産規模に適しています。正確な数値は、提供される落花生の品種や水分含量に応じて調整可能です。

ピーナッツの殻を剥く際の破損率はどのくらいですか?

私たちの機械は破損率を2%未満に維持し、ピーナッツのカーネルへの損傷を最小限に抑えています。機械の構造は、異なる殻の硬さを持つピーナッツを扱うために最適化されています。

機械のメンテナンス頻度とケアの要件は何ですか?

日常運転の前に、シェルリングセクションと伝送システムに焦点を当てた基本的な清掃と点検を推奨します。400作業時間ごとに行う完全なメンテナンスには、部品の潤滑と締め付けが含まれており、長期的な効率的運転を確保します。

この機械はどのピーナッツの品種や仕様に適していますか?

当社の落花生殻剥き機は、硬殻および軟殻のさまざまな落花生品種に対応しており、異なるサイズの落花生の殻剥きもサポートしています。ユーザーは、最適な殻剥き性能を得るために、特定のタイプに応じて機械のパラメータを調整できます。