Entrega de máquinas prensadoras de aceite de maní a Irán

Recientemente, nuestra fábrica completó la producción de un lote de prensas de aceite de maní y las entregó a Irán, lo que marca un hito importante para un distribuidor recién establecido que ingresa a la industria del prensado de aceite de maní.

Antecedentes del cliente

Como nuevo distribuidor, este cliente ha establecido recientemente una fábrica de prensado de aceite de maní en Irán y tiene como objetivo mejorar el mercado local de aceite comestible utilizando equipos mecanizados avanzados. El cliente visitó China para evaluar el equipo y, a través de exhaustivas discusiones y experiencia práctica, expresó un gran interés en el rendimiento, la eficiencia de producción y el servicio posventa del equipo.

Demanda de prensas de aceite de maní

El objetivo principal del cliente es procesar de manera eficiente y consistente grandes volúmenes de materia prima de maní para producir aceite de maní de alta calidad para el mercado local. Describió varios requisitos clave para la prensa de aceite:

- El cliente solicitó prensas de aceite de maní que ofrecieran funciones de prensado en frío y en caliente para adaptarse a diversas técnicas de procesamiento, preparando el escenario para una futura diversificación de productos.

- Le preocupa especialmente la capacidad de la máquina para manejar de forma fiable grandes cantidades de materiales. Las prensas de aceite fabricadas por nuestra fábrica están construidas para brindar alta eficiencia y durabilidad, diseñadas para soportar operaciones de producción exigentes.

- El cliente pone gran énfasis en la confiabilidad del equipo tanto durante la instalación como durante el funcionamiento. Para abordar esto, nos dedicamos a brindar servicios exhaustivos de inspección de calidad y enviar técnicos para ayudar a los clientes con la instalación y puesta en servicio del equipo, garantizando un proceso de producción perfecto.

Si está interesado en esta prensa de aceite de tornillo, haga clic Extractor de aceite de maní | Expeller de aceite de maní.

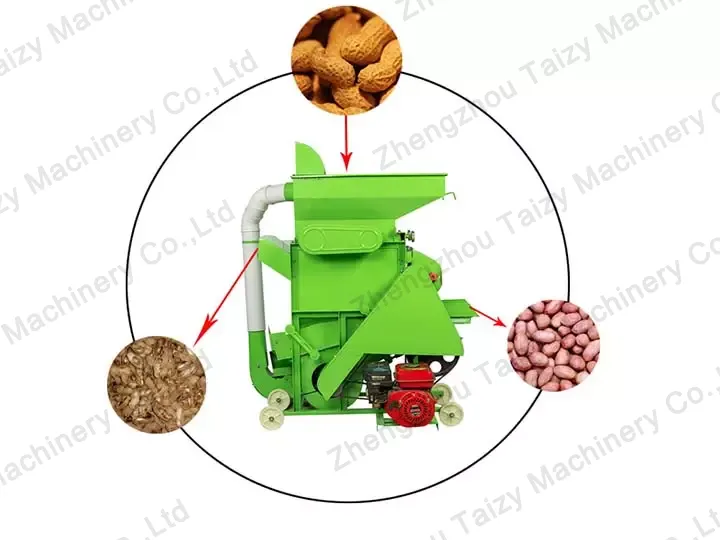

Detalles del equipo enviado

- Esta máquina admite procesos de prensado en frío y en caliente, lo que permite a los clientes ajustar su flujo de producción fácilmente.

- Está diseñado para brindar eficiencia y estabilidad, lo que lo hace ideal para procesar grandes volúmenes de materiales de maní.

- Construido con acero inoxidable de alta calidad, garantiza una larga vida útil y cuenta con control automático de temperatura junto con una interfaz de operación digital, lo que simplifica el proceso de producción para los usuarios.

Para satisfacer aún más las necesidades de producción futuras de los clientes, también recomendamos y suministramos accesorios esenciales como ejes de tornillo y dispositivos de filtración, que mejoran la compatibilidad y eficiencia del equipo.

Comunicación y servicio profesional.

Durante nuestra colaboración, el cliente expresó su preocupación por la rentabilidad y solicitó un descuento en el total de la compra. Después de cuidadosas discusiones, llegamos a un precio que satisfizo a ambas partes. El cliente también elogió los accesorios sugeridos por nuestra fábrica y se mostró abierto a implementar nuestras recomendaciones profesionales para mejorar el proceso de producción.