Kommerzielle Erdnuss-Frittiermaschine, Lebensmittelfritteuse aus Edelstahl

| Modell | TZ-RG1200 |

| Größe | 1650x1400x1700mm |

| Entladeleistung | 0,75 kW |

| Mitreißende Kraft | 0,75 kW |

| Heizleistung | 200000 Kilokalorien |

| Größe der Bratzone | 1200x350mm |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

Die Erdnuss-Bratmaschine eignet sich ideal zum Braten von Nüssen, Puffsnacks, Nudelgerichten, Fleisch, Meeresfrüchten und Sojaprodukten. Es wird häufig in Erdnussverarbeitungsbetrieben und Lebensmittelproduktionsbetrieben eingesetzt.

Diese Fritteuse verfügt über ein automatisches Öltemperaturkontrollsystem und bietet zwei Heizoptionen: Elektro und Kohle. Mithilfe modernster Öl-Wasser-Mischtechnologie werden Rückstände automatisch herausgefiltert, was zu einer Reduzierung des Ölverbrauchs um 501 TP3T und einer Reduzierung des Stromverbrauchs um 401 TP3T führt.

Anwendungen für Lebensmittelfrittiermaschinen

Die Lebensmittelfritteuse ist ideal für die Lebensmittelindustrie, Fast-Food-Restaurants, Brathähnchenläden, Konditoreien und mehr. Hier ist eine kurze Liste verschiedener Arten von Lebensmitteln, die zubereitet werden können:

- Nüsse: Saubohnen, Erbsen, Erdnüsse, Pinienkerne.

- Puffsnacks: Potpourri, Kartoffelchips.

- Nudelgerichte: Katzenohren, Muschelkuchen, Donuts, Sachima, Potpourri.

- Fleischgerichte: Hackbraten, Hähnchenschenkel.

- Meeresfrüchte: Gelber Lachs, Jakobsmuscheln.

- Sojaprodukte: getrockneter Tofu, Tofu-Puffs und andere.

Funktionsprinzip der Erdnuss-Bratmaschine

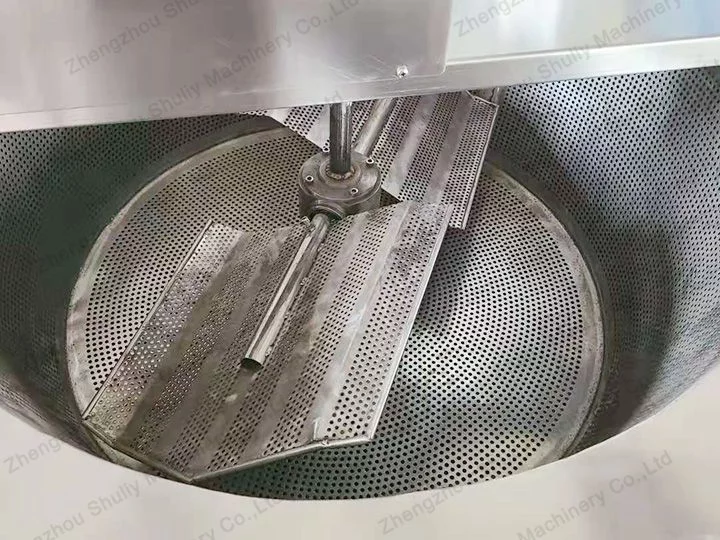

- Die Erdnussöl-Frittiermaschine nutzt hauptsächlich Strom oder Gas als Wärmequelle und treibt die interne Mischvorrichtung über ein Übertragungssystem in Auf- und Abwärtsbewegungen.

- Wenn die Öltemperatur steigt, wird das Material in die Maschine gegeben und die Selbstrührfunktion sorgt dafür, dass das Material gleichmäßig frittiert wird. Eventuelle Rückstände, die beim Frittieren entstehen, setzen sich am Boden ab, was die Lebensdauer des Öls verlängert.

Diese Maschine verwendet einen fortschrittlichen Misch- und Zuführprozess, der das gleichzeitige Mischen der frittierten Lebensmittel ermöglicht und gleichzeitig das Wasser nach dem Mischen automatisch von den frittierten Produkten trennt. Das Frittiergut bleibt auf der oberen Schicht, während sich das Öl darunter absetzt, wodurch das Frittiergut sauber bleibt und Abfall minimiert wird.

Technische Parameter

Wir bieten elektrische und gasbeheizte Erdnussbratmaschinen an. Darüber hinaus bieten wir Optionen basierend auf der Form an, wobei sowohl runde als auch quadratische Maschinen verfügbar sind. Die Wahl hängt letztendlich vom Standort des Kunden und seinen persönlichen Vorlieben ab.

Runde, gasbeheizte Fritteuse

| Modell | TZ-RG1000 | TZ-RG1200 | TZ-RG1500 |

| Größe (mm) | 1450x1200x1700 | 1650x1400x1700 | 1950x1600x1700 |

| Entladeleistung (kW) | 0.75 | 0.75 | 1.1 |

| Rührleistung (kW) | 0.75 | 0.75 | 1.5 |

| Heizleistung | 100.000 Kilokalorien | 200.000 Kilokalorien | 200.000 Kilokalorien |

| Bratzonengröße (mm) | 1000×350 | 1200×350 | 1500×350 |

Runde, elektrisch beheizte, gewerbliche Lebensmittelfritteuse

| Modell | TZ-RE1000 | TZ-RE1200 | TZ-RE1500 |

| Größe (mm) | 1250x1200x1700 | 1450x1400x1700 | 1750x1700x1700 |

| Entladeleistung (kW) | 0.75 | 0.75 | 1.5 |

| Rührleistung (kW) | 0.75 | 1.1 | 1.5 |

| Bratzonengröße (mm) | 1000×350 | 1200×350 | 1500×350 |

Quadratische Fritteusenmaschine mit elektrischer Heizung

| Modell | TZ-SE1000 | TZ-SE1500 | TZ-SE2000 |

| Größe (mm) | 1400x1100x1700 | 1900x1100x1700 | 2400x1100x1700 |

| Entladeleistung (kW) | 0.75 | 0.75 | 1.5 |

| Heizleistung (kW) | 40 | 60 | 90 |

| Bratzonengröße (mm) | 1200×800 | 1500×800 | 2000×800 |

Quadratische Fritteuse mit Gasheizung

| Modell | TZ-SG1000 | TZ-SG1500 | TZ-SG2000 |

| Größe (mm) | 1400x1500x1700 | 1900x1500x1700 | 2400x1500x1700 |

| Entladeleistung (kW) | 0.75 | 0.75 | 1.5 |

| Heizleistung | 100.000 Kilokalorien | 200.000 Kilokalorien | 200.000 Kilokalorien |

| Bratzonengröße (mm) | 1200×800 | 1500×800 | 2000×800 |

Oben sind die technischen Parameter von 4 Fritteusenmaschinen aufgeführt. Wenn Sie eine hochwertige Erdnussbratmaschine benötigen, können Sie uns jederzeit kontaktieren.

Highlights der Erdnussbratmaschine

- Rührgerät. Der Rührmechanismus in der Maschine sorgt dafür, dass jede Erdnuss gleichmäßig frittiert wird und verhindert gleichzeitig, dass die Paste am Boden kleben bleibt.

- Automatische Temperaturregelung. Wenn die Öltemperatur den voreingestellten Wert überschreitet, schaltet sich die elektrische Heizung (Brenner) automatisch ab. Diese Funktion trägt dazu bei, die ideale Frittiertemperatur für die Erdnuss-Frittiermaschine aufrechtzuerhalten und so die Qualität des Endprodukts zu verbessern.

- Automatisches Entladen. Mithilfe eines Motorlifts kann die Maschine das Material automatisch entladen, sobald das Frittieren abgeschlossen ist. Diese Funktion reduziert die körperliche Belastung der Arbeiter erheblich.

- Die Maschine besteht aus Edelstahl 304, der für seine Festigkeit und Haltbarkeit bekannt ist und somit rostbeständig ist.

- Die in der Maschine verwendete Isolierbaumwolle besteht aus Aluminiumsilikat, ein neuartiges umweltfreundliches Dämmmaterial. Es speichert die Wärme effektiv und minimiert den Stromverbrauch.

Wie bereitet man Erdnüsse vor dem Braten zu?

- Wählen Sie frische rohe Erdnüsse.

- Entfernen Sie die Schalen und Häute von den Erdnüssen. Eine Erdnussschälmaschine und eine Nass-Erdnussschälmaschine können für diese Aufgabe hilfreich sein.

- Spülen und trocknen Sie die Erdnüsse nach der Verarbeitung.

- Heizen Sie die Fritteuse auf etwa 175 °C vor. Sie können ein Thermometer verwenden, um sicherzustellen, dass das Öl die richtige Temperatur hat.

- Die Erdnüsse in das heiße Öl geben.

- Frittieren Sie sie, bis sie je nach Wunsch eine goldbraune oder dunkelbraune Farbe haben. Dies dauert normalerweise etwa 10 bis 15 Minuten.

- Sobald Sie fertig sind, gießen Sie die gebratenen Erdnüsse zum Abkühlen aus. Darüber hinaus ist es wichtig, regelmäßig zu trainieren Warten Sie Ihre Erdnussbratmaschine um seine Langlebigkeit zu gewährleisten.

Wo kann man eine automatische Fritteuse kaufen?

Mit über 20 Jahren Erfahrung im Maschinenbau bieten wir nicht nur hochwertige Maschinen zum Frittieren von Erdnüssen, sondern auch Erdnussschälmaschinen, Maschinen für geröstete Erdnüsse, Und Ausrüstung zur Herstellung von Erdnussbutter, unter anderem. Wenn Sie Erdnussmaschinen benötigen, zögern Sie bitte nicht, sich an uns zu wenden.