Vorteile der automatischen Erdnussbeschichtungsmaschine von Taizy

Erdnüsse können in verschiedenen Formen zu Erdnüssen mit unterschiedlichen Geschmacksrichtungen verarbeitet werden. Eingewickelte Erdnüsse sind eine davon. Überzogene Erdnuss ist eine Snack Lebensmittel, die hergestellt werden, indem eine automatische Erdnussbeschichtungsmaschine verwendet wird, um die Erdnussschale mit Mehl und anderen Zutaten zu überziehen, und anschließend gebacken und andere Prozesse durchgeführt werden.

Prozessablauf von beschichteten Erdnüssen

Backen – Beschichten – Trocknen – Backen – Kühlen – Würzen – die Verpackung

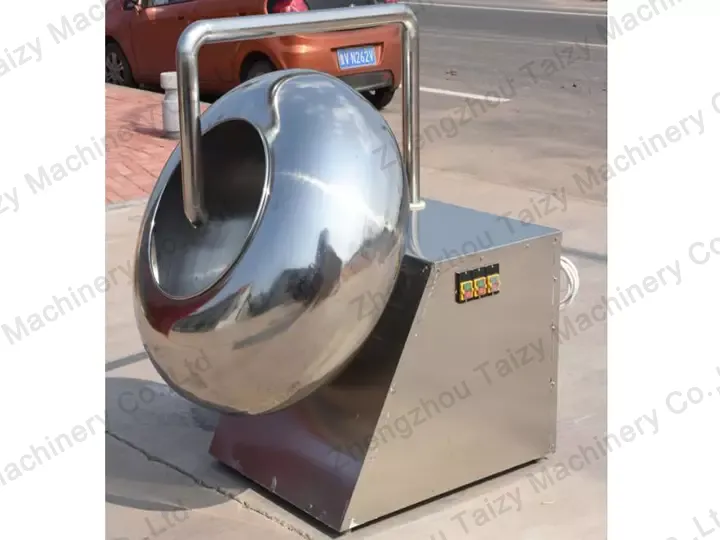

Die Produktionslinie für die Verarbeitung von beschichteten Erdnüssen besteht hauptsächlich aus einer automatischen Beschichtungsmaschine, einem Zufuhraufzug, einer Vakuummehlzuführung usw. Die Erdnussbeschichtungsmaschine besteht aus einem Beschichtungssystem, einem quantitativen Zuführsystem, einem quantitativen Pulverversorgungssystem, einem quantitativen Flüssigkeitsversorgungssystem usw Hauptrahmen.

Vorteile der automatischen Erdnussbeschichtungsmaschine

- Die Produktqualität der Produktionslinie zur Verarbeitung beschichteter Erdnüsse ist stabil, die Einzelmaschinenleistung ist groß, es gibt keine Staubverschmutzung und es kann kontinuierlich produziert werden.

- Der hohe Automatisierungsgrad. Verschiedene Gewürzrezepturen und Produktarten können mit einer Taste gespeichert werden.

- Der Ausrüstung zum Überziehen von Nüssen kann die Erdnussoberfläche gleichmäßig mit Pulver beschichten. Die Grundform des Materials bestimmt die Form des Formteils.

- Mit einem einzigen Schlüsselvorgang können Sie die Produktion von der Pulverzufuhr über das Backen und Würzen bis hin zur fertigen Beschichtung abschließen. Dadurch wird die Stabilität und Einheitlichkeit der Qualität der fertigen Produkte gewährleistet und die Staubbelastung der Werkstattumgebung verringert. Dies verringert nicht nur die Intensität der menschlichen Arbeit erheblich, sondern verringert auch die Qualifikationsanforderungen für die Bediener und lindert das Problem der Rekrutierungsschwierigkeiten für Unternehmen.

Wenn Sie bereit sind, das Verarbeitungsgeschäft von überzogenen Erdnüssen mit einer automatischen Erdnussüberzugsmaschine zu erweitern, hinterlassen Sie bitte Ihre Kontaktinformationen. Wir werden uns mit Ihnen in Verbindung setzen, um wettbewerbsfähige und exklusive Lösungen entsprechend den Produktionsanforderungen anzubieten.