How to Maintain the Commercial Peanut Roasting Machine?

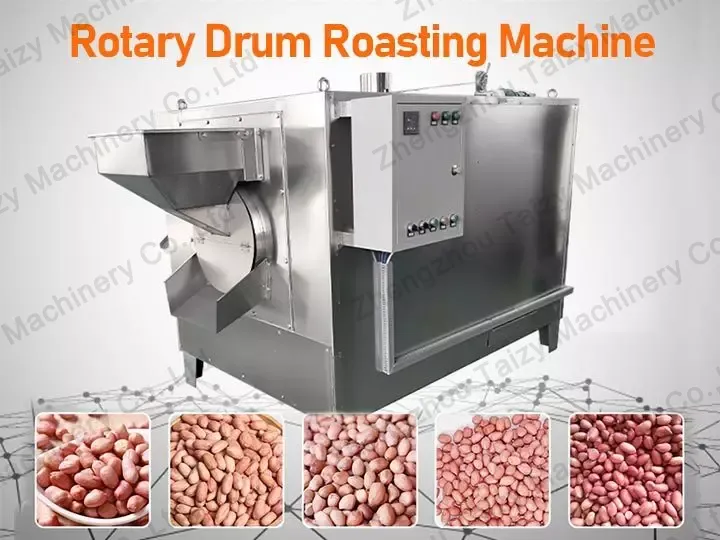

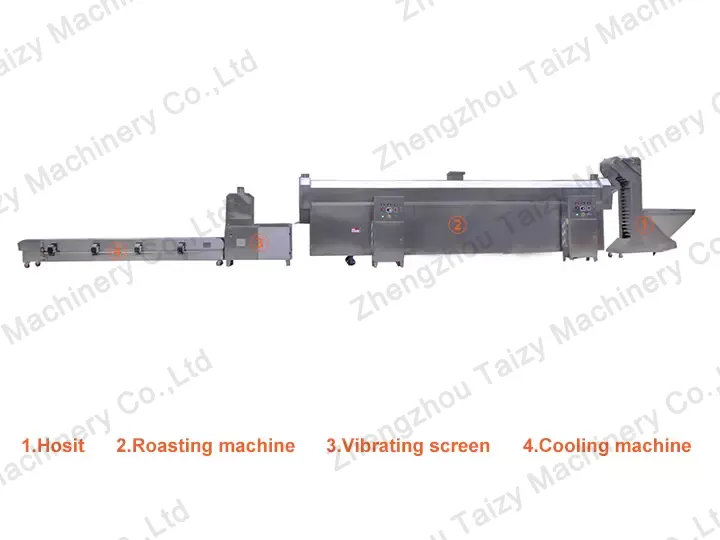

The commercial peanut roasting machine is a widely used peanut machinery and equipment in peanut deep processing. The quality of the roaster machine is important, but the daily maintenance of the equipment is also indispensable. commercial peanut roasting machine maintenance must follow a certain system and process. This can promote this machine to give full play to the performance.

The commercial peanut roasting machine maintenance system

- Comply with the maintenance and repair system developed by the enterprise. Ensure the normal operation of the groundnut roasting machine.

- Equipped with special commercial peanut roasting machine maintenance personnel. At the same time, the relevant personnel should be technical training. Training and assessment before they are qualified to work.

- In the development of the annual production and operation plan at the same time, as the development of the baking machine annual repair and maintenance plan. And refine it to quarterly, monthly, and weekly. In time, money and manpower, and other aspects of implementation are in place.

- Keep detailed records of each repair and maintenance. Based on experience, analyze the causes of failure and form the experience of troubleshooting.

Commercial peanut roasting machine maintenance process

- The operator should be familiar with and master the performance, structure, processing range, and maintenance techniques of the peanut roasting equipment.

- Regular inspection of the equipment. Clean the exterior and outer cover of the roaster. Timely removal of oil and ash accumulation, etc. Maintain the overall cleanliness and hygiene of the baking machine. Regularly carry out partial disassembly of the baking machine to inspect and refurbish the structure of the parts. Clear the clearance of foreign matter of transmission parts and bearings, and replace the damaged parts in time when found. Check and adjust the mesh belt, remove the rolled edges on both sides of the mesh belt and the debris and oil stuck on the mesh belt. Regularly check whether the power supply or air supply route is unobstructed. Check and clean all lubrication points to keep lubrication normal and eliminate oil leakage. Fasten the screws and nuts of all parts to make them firm and reliable.

- Every 6-12 months, check all aspects of the baking machine, and partially replace and repair some worn parts. Check all transmission mechanisms, clean and change oil, and repair and replace worn parts. Check and repair all the heater devices and automatic control system. Check and clean the mesh belt, no cracks and rolled edges. The joints should be flat and polished. If damage is found, a partial or full mesh belt needs to be replaced. The mesh belt should be oiled after cleaning.

Summary

Taizy peanut processing machinery has rich experience in research and development and production of peanut roasting machine. If you have any questions about the purchase and maintenance of a commercial peanut roasting machine, please feel free to contact us.