Peanut Brittle Forming and Cutting Machine | Peanut Cereal Bar Forming Machine

Peanut Bar Making Machine | Cereal Bar Forming Machine

Model: TZ-300

Capacity(kg/h): 300-400

Width of peanut brittle: Adjustable

Width of pressing roller(mm): 560

Total length(mm): 11800

Length of conveyor belt(m): 5

Length of the conveyor belt(m): 4

Number of the pressing roller: 5(0.75kw)

Raw material: 201 stainless steel

Secondary cutting device: 220v 250w

The peanut brittle forming and cutting machine is the main machine in the peanut candy production line. As the name suggests, the function of the peanut brittle machine is to flatten the candy/brittle and cut it into uniform sizes.

It can not only make peanut brittle/candy, but also can make sachima, various cereal bars, sesame candy, sunflower candy, and so on.

How is peanut brittle made?

The peanut brittle production process does not only need one machine to complete. In addition to the peanut brittle forming and cutting machine, a peanut roasting machine, a peanut peeling machine, a jacket kettle, a peanut candy mixer, and a peanut brittle packaging machine are also required.

The complete peanut brittle making process

First, we need to roast and peel the peanuts. Then boil the syrup in a peanut brittle jacketed pot. Then pour the peeled peanuts into the syrup and mix well. Next, the mixed peanuts and syrup are sent to the peanut candy forming and cutting machine for shaping and cutting. Finally, after the peanut candy/brittle is cooled, it can be packaged.

Parameters of peanut cereal bar forming machine

| Model | TZ-300 |

| Capacity(kg/h) | 300-400 |

| Width of peanut brittle | Adjustable |

| Width of pressing roller(mm) | 560 |

| Total length(mm) | 11800 |

| Length of conveyor belt(m) | 5 |

| Length of the conveyor belt(m) | 4 |

| Number of the pressing roller | 5(0.75kw) |

| Raw material | 201 stainless steel |

| Secondary cutting device | 220v 250w |

The above are just the parameters of a peanut brittle forming and cutting machine. In addition, we also have other styles of machines for sale. The output range is from 100kg/h to 2000kg/h. If necessary, please feel free to contact us, and we will reply to you as soon as possible.

Working principle of peanut cereal bar forming machine

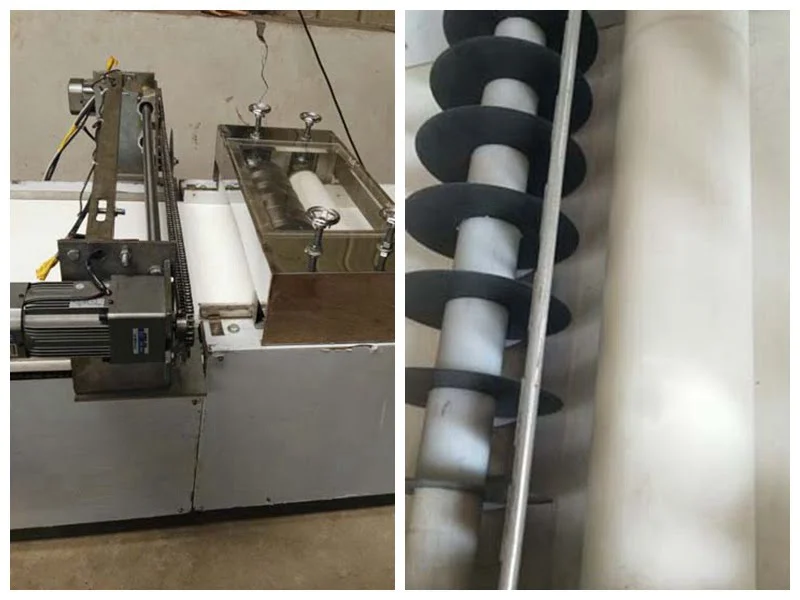

The peanut candy molding machine is mainly composed of a compacting system, a cooling system and a cutting system.

First, workers need to feed the mixed syrup and peanuts into the machine. Then the inside of the machine will automatically heat and stir the peanut brittle. Then shake and wiggle to gradually form solid peanut crumbs.

After the peanut candy is cooled in the cooling system, the peanut brittle forming and cutting machine will automatically cut it into the desired shape and size. Our machines can adjust the cutting size and shape as needed to meet different production needs.

The peanut brittle forming machine can greatly improve the production efficiency of peanut brittle. At the same time, it can also reduce manual operation and labor intensity. It is one of the important pieces of equipment for the production of peanut candy in modern factories.

Features of the peanut brittle forming and cutting machine

- The high degree of automation. The peanut candy forming and cutting machine can realize automatic production and improve production efficiency.

- 201 stainless steel material makes the machine have the characteristics of long service life and hygiene.

- The width of peanut brittle/candy can be adjusted according to customer needs.

- Saving raw materials: The machine can precisely control the amount and shape of raw materials.

- High safety: The operation of the machine is safer than manual operation, which reduces the risk of work-related injuries for workers.

- Wide range of applications.

Contact us

Do you need a peanut cereal bar forming machine, a cereal bar forming machine, or a cereal bar line? If you are interested, please feel free to contact us, and we will reply to you as soon as possible.